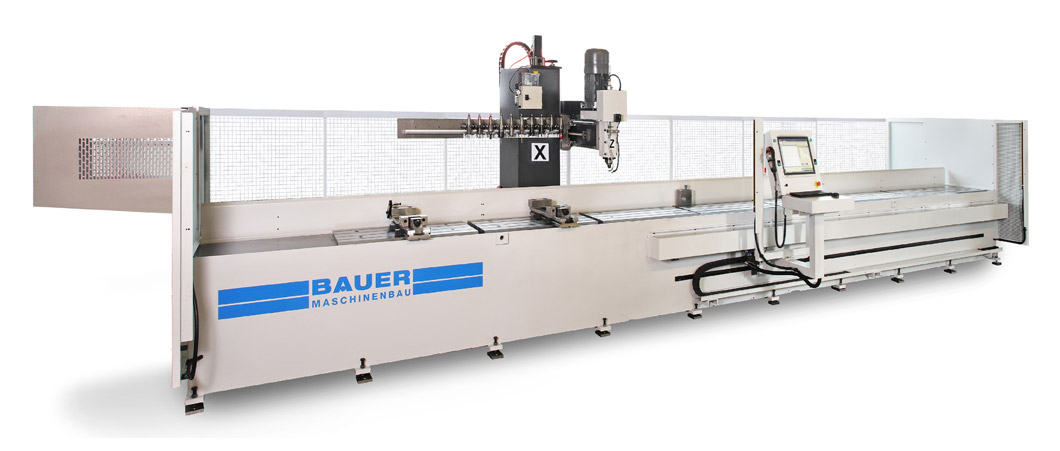

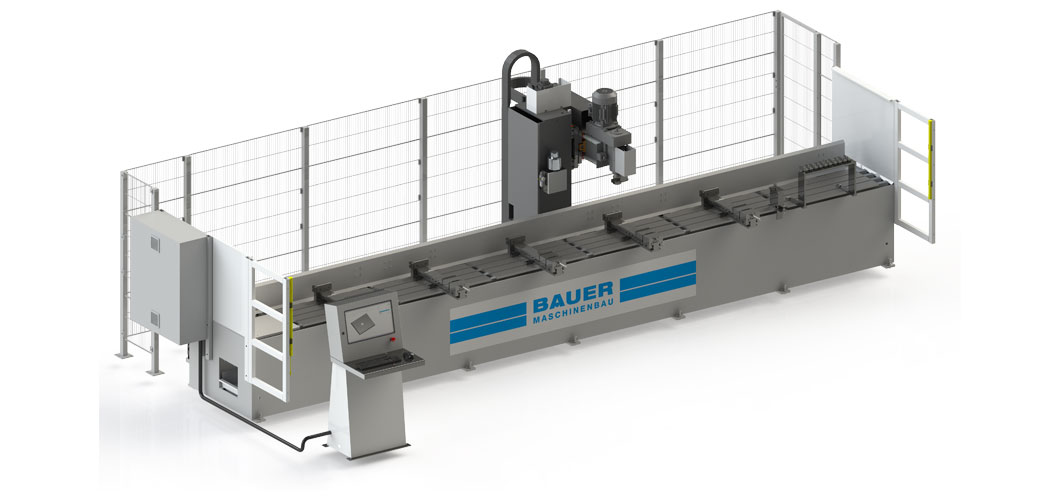

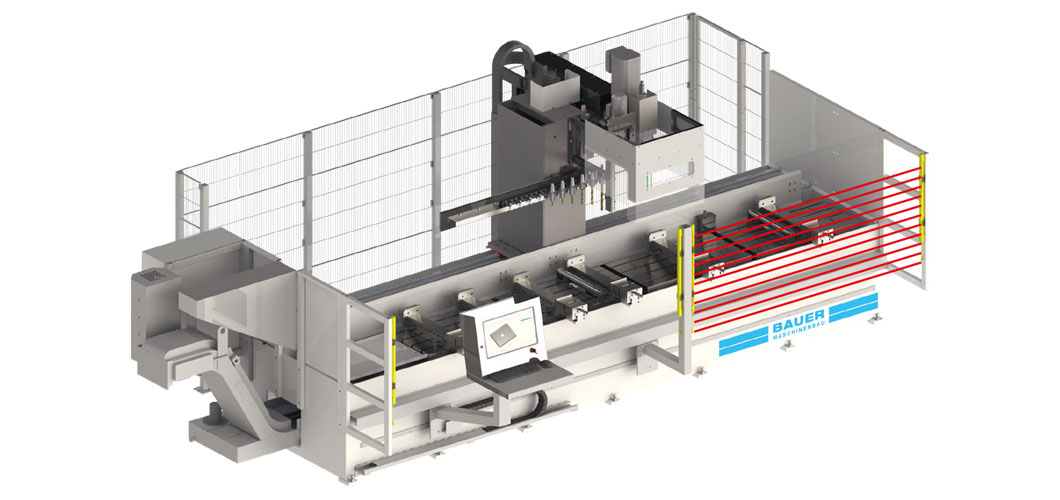

BAUER BOHRMAX Z

Drilling and milling of long parts.

Machine length up to 8 meters!

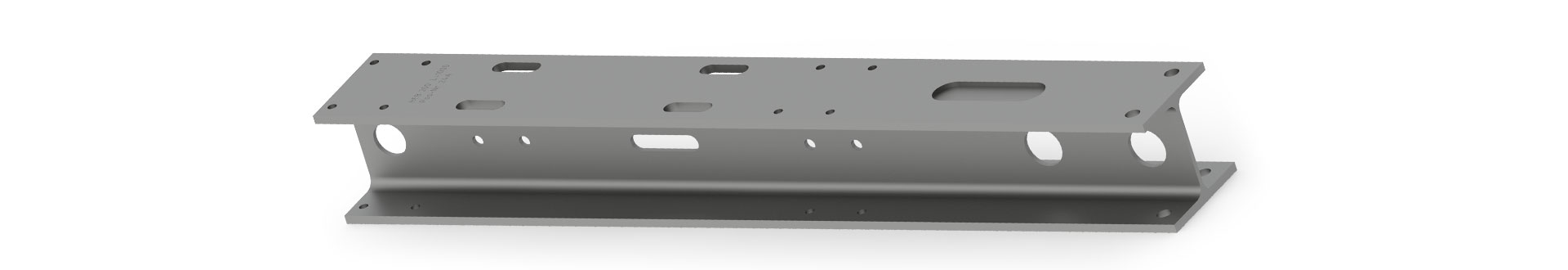

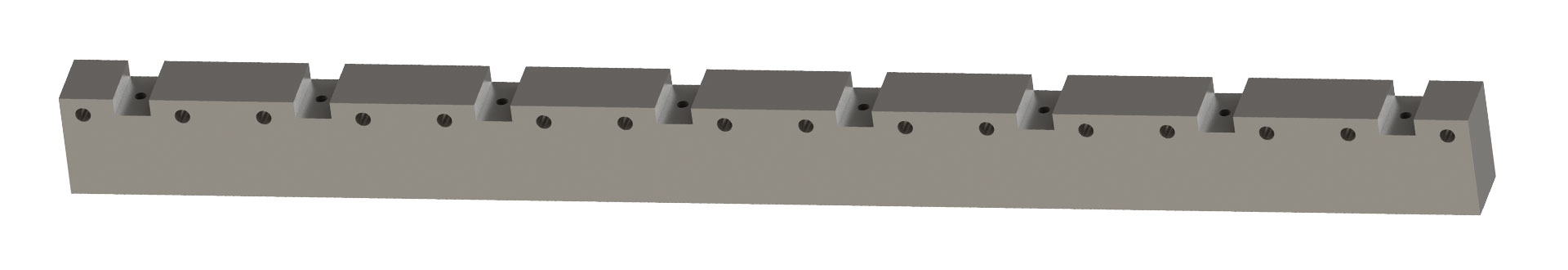

You produce such parts?

No problem with the BAUER BOHRMAX.

Whether drilling, milling, long holes, circles, breakthroughs,

cutting threads or drilling casting holes. MACHINING LENGTH UP TO 8 METERS

No problem with the BAUER BOHRMAX. Everything without programming knowledge.

Easier and more time-saving than any other machine!

Machining length up to 8 meters!

Technical Data BOHRMAX Z:

- Drilling head speed range 140-4000 rpm

- Drive X, Y, Z Axis: Servomotor

- Rapid traverse X axis: 24 m/min

- Rapid traverse Y axis: 7.5 m/min

- Rapid traverse axis: 7.5 m/min

- Distance table top edge – lower edge tool holder 700 mm

- Table width: 560 mm

- T-slots M 12

- Drill diameter: 3- 40 mm

- Tapping: M 4 – M 30

- Tolerance X axis: ± 0.1 mm

- Tolerance Y and Z axis: 0.06 mm

- Drilling head drive motor: 7.5 kW

- Front light barrier

- Rear access guarding, on-site

- Control: Touchscreen 21“

- Simple programming on the machine

- Milling of oblong holes and circles

- Cooling

Options:

- Vices manual

- Support rollers

- Spray mist system

- Manual control unit

- Chip conveyor

- Movable chip & splash guard

- Angle head

- Pendulum operation

- Automatic tool length measurement

- Spray device in addition to water cooling

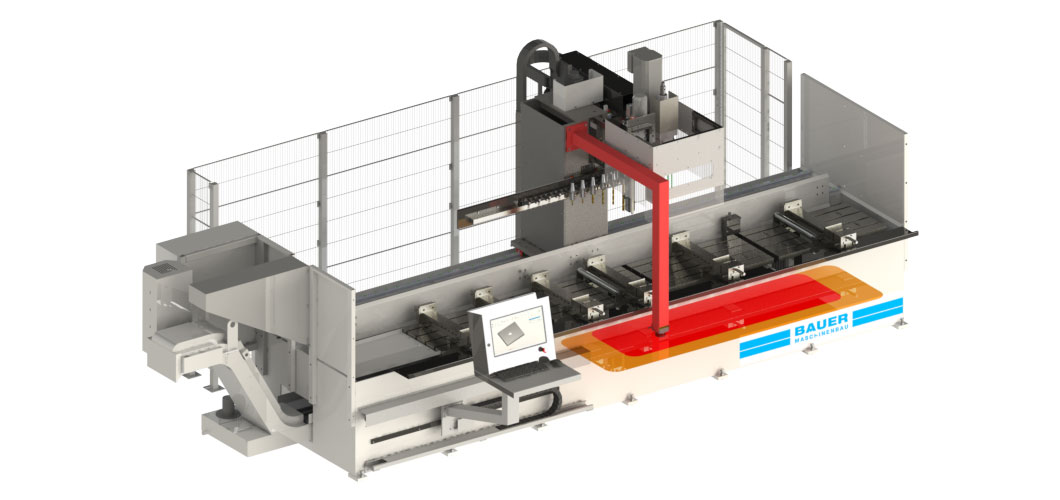

BAUER BOHRMAX LIGHT

Fully Automatic Drilling System

The Entry-Level Model

BOHRMAX LIGHT 60 L

Technical Data BOHRMAX LIGHT:

- Speed range drilling head 140-2000 rpm

- Drive Y+Z +X Axis: Servomotor

- Rapid traverse X axis: 24 m/min

- Rapid traverse Y+ Z axis: 7.5 m/min

- Distance table top edge – bottom edge tool holder 500 mm

- Table width: 360 mm

- T-slots M12

- Tapping: M4 – M20

- Tolerance X-axis+/-: 0.2 mm

- Tolerance Y and Z axis +/-: 0.1 mm

- Drilling head drive motor: 2.2 kW

- Front light barrier

- Rear access guarding, on-site

- Quick-change chuck Laip

Options:

- Automatic tool length measurement

- Vises

- Coolant system

- Tool changer pick up 5 tools

BAUER BOHRMAX

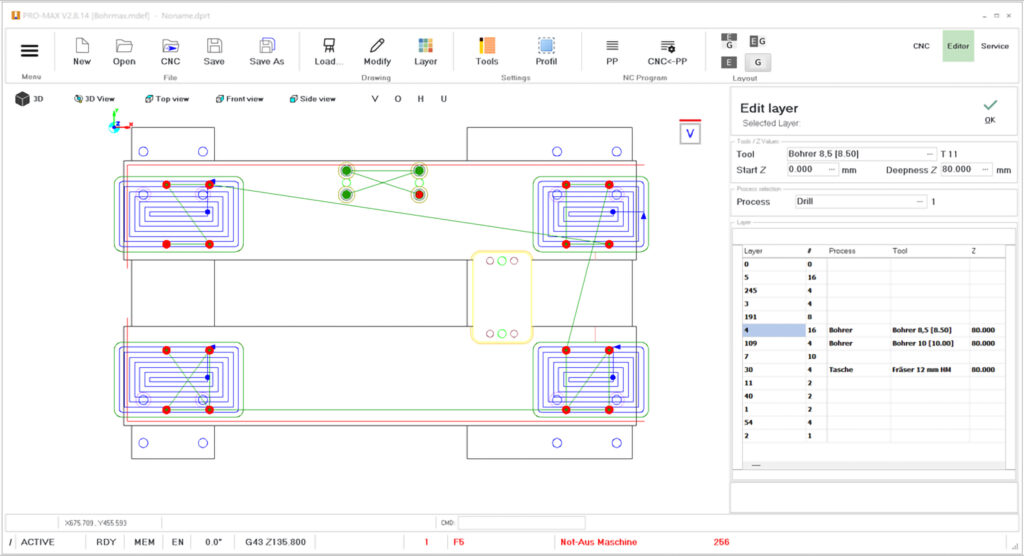

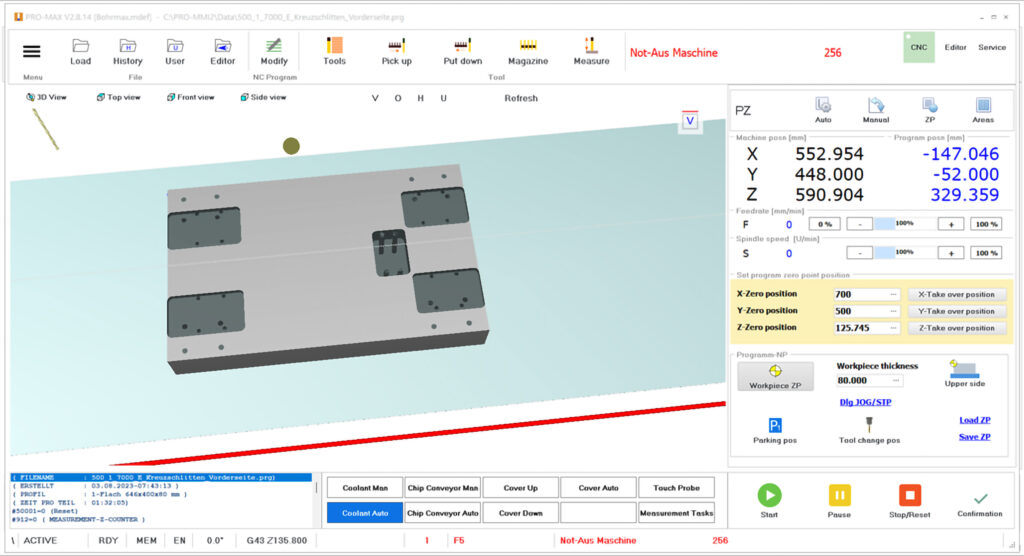

Control & Programming

- Clear, graphical user interface

- Easy Programming & Control

- Produce after one hour of instruction

- NO CNC knowledge needed!

- Developed in collaboration with Mitsubishi Electric

There is no simpler EASY-TO-USE control on the market!

Access security:

Standard scope of delivery:

Left & right access protection via light barrier.

Access protection at the back by the customer

or rear protective fence option.

Option – safety laser scanner:

A traveling laser scanner is used the protected area is monitored.

The area is shown in color in the figure.

In practice the area is “not visible”.

If you enter the red area, the machine stops.

The machine stops in the orange area.

Option – Slidable light barrier for shuttle operation:

For example, if the machine works on the left side, the right light barrier must be released for re-tightening new parts. The right light barrier is then “armed” by pressing a button on the control panel.

When the machine is finished with the left side, it automatically switches to the right side and the parts are processed. At the same time the left side is released.

BAUER BOHRMAX Z20 – Z80

Models – Equipment Variants

| TYPE Procedure | X-axis (mm) Traverse path | Y-axis (mm) Traverse path | Z-axis (mm) Traverse path |

|---|---|---|---|

| BOHRMAX Z20 | 2100 | 580 | 700 |

| BOHRMAX Z30 | 3050 | 580 | 700 |

| BOHRMAX Z40 | 4050 | 580 | 700 |

| BOHRMAX Z60 | 6100 | 580 | 700 |

| BOHRMAX Z80 | 8050 | 580 | 700 |

| BOHRMAX LIGHT 30 L | 3050 | 400 | 400 |

| BOHRMAX LIGHT 60 L | 6050 | 400 | 400 |